New model to tackle excessive steel capacity

Updated: 2014-01-03 10:00

By Du Juan (China Daily Europe)

|

|||||||||||

|

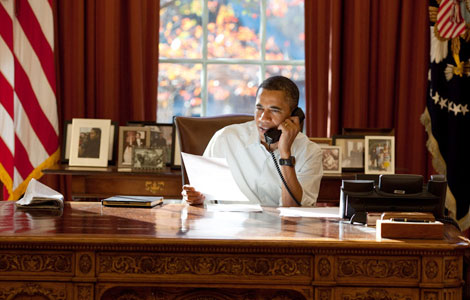

Yu Yong, president of Tangsteel, says cooperation with Duferco of Switzerland has eased financial pressure and helped diversify marketing channels. Provided to China Daily |

Structured financing deals help Chinese firms increase finished product exports

Against the background of the overcapacity problem in China's steel industry, Deutsche Bank AG says that it has, together with Switzerland's Duferco SA, an international steel dealer, arranged an $800 million structured prepayment term loan facility for Tangsteel in Tangshan, an industrial city in northeastern Hebei province.

It is the largest structured commodity trade financing facility ever completed for a Chinese company.

"Like Tangsteel, there are many strong and active players in the steel industry in China that continue to contribute to its economic growth. This round of financing is meant to support Tangsteel's export of high-end cold rolled steel products," says Frank Wu, regional head of structured commodity trade finance, Asia-Pacific, for global transaction banking at Deutsche Bank.

He says increasing exports of steel products from such Chinese companies can help utilize the capacity in the domestic market.

Behind this comprehensive and supportive cooperation among the international bank, steel trader and the Chinese steelmaker is a "smart model" for making full use of the advantages of each party to survive the market, says Zhang Tieshan, a senior analyst from steel information provider Mysteel.com.

"There are various ways for Chinese steel companies to go abroad in addition to just selling products," he says.

In March, Tangsteel acquired a 10 percent stake in Switzerland's Duferco International Trade Holding, the world's biggest steel trader, as a start to expanding its operations in the international market.

At that time, the two companies signed a steel products structural payment agreement worth $1.2 billion, which gave Tangsteel a relatively more stable channel to sell its products abroad in the face of a gloomy domestic market.

"This global strategy is the key to Tangsteel's development," says Yu Yong, president of Tangsteel, who was also named president of Hebei Iron and Steel Group, Tangsteel's parent company, earlier this month.

Hebei Iron and Steel Group is the largest steel company in the country by output.

"The cooperation with Duferco has eased Tangsteel's financial pressure and increased the diversification of its marketing channels," says Yu.

He added that the cooperation will help provide Tangsteel with better financial services and access to resources such as raw materials from international iron ore giants.

"The internationalization is to make the best use of resources globally, especially good existing platforms and business models," he says.

Over the past year, Duferco's steel trade volume was more than 16 million metric tons, equal to the total output of HBIS.

Through its distribution channels, steel products can be sold to 28,000 end customers in Europe, North America and South America.

By cooperating with Duferco, Tangsteel's exports during the first 11 months of 2013 increased 96 percent year-on-year to 2.79 million tons, according to data from the company.

For the same period in 2012, Tangsteel's export figure was 1.42 million tons.

Yu estimated that the figure will reach 4 million tons this year.

In 2009, when the two companies had just started cooperation, Tangsteel's exports to Duferco was only 67,000 tons.

In addition to increasing exports, the steel trader can also help the Chinese company improve its technology.

"It is the first time that a Chinese steelmaker has invested in our company. Duferco has long held the belief that our long-term future lies firmly alongside the developing economies," says Matthew De Morgan, Duferco's chief executive officer. "We will help Tangsteel improve its technology and introduce its steel products to other international markets besides Asia."

"The model is rare in China, but it is very mature in Europe and Japan," says Zhang. "It can effectively tie up the interests of steel traders and steel makers, which will lead to better mutual profits."

In Japan, many large-scale steel traders own shares in steelmakers, and vice versa. They also invest in upstream resources such as mining companies to ensure stable iron ore supplies.

"It is better for companies to focus on their own strengths when the steelmakers don't need to worry about marketing and traders don't have to seek out enough supplies," he says.

"Among all the Chinese steel companies, Tangsteel has its own specialty to attract foreign investors," says Zhang.

China's steel industry has been suffering from rising iron ore costs and falling steel prices in recent years, with many companies suffering huge losses or weak profits.

However, Tangsteel achieved a better performance compared with other producers that focus on the production of steel sheets and plates, which form the major element of the excessive supply in the market, Zhang says.

"Tangsteel mainly produces steel products for the construction sector, which still has enough demand driven by the rising real estate market," he says. "In addition, the steel products for auto-making have been profitable."

Hu Yanping, a steel analyst with Umetal.com, says common-use steel sheet products for electronic appliances cost about 4,400 yuan ($690) a ton, while the ones for automobiles are priced at about 5,300 yuan.

Tangsteel will cooperate with Duferco in a project for high-end steel products for automobile manufacturing. The project is scheduled to start production by the end of this year, according to the Chinese steelmaker.

Despite the supportive voices, some experts warned that Tangsteel's model cannot easily be copied by other Chinese steel companies.

Li Xinchuang, head of the China Metallurgical Industry Planning and Research Institute, says the model is still in its early stages and it will take time to see whether it will be successful and cope with changes in the market.

He says there are many stages and various ways to enter other countries, not only selling steel products to foreign markets, which is possibly the major strategy for Chinese companies' "going overseas" at present.

Because of the high-energy use and environmental costs of the steel production process, the Chinese government does not encourage steel products to be exported. However, facing the current severe overcapacity problem, it does not discourage exports, either.

Zhang says European steel companies choose to expand their overseas business through establishing steel mills in foreign lands, especially in developing countries where there is growing demand.

Meanwhile, Li says there are still potential markets to explore within the country, such as the construction and stainless steel application sectors.

Zhejiang Hangxiao Steel Structure Co Ltd, China's first listed architectural steel structure company, formed a strategic cooperation with Tangsteel on Nov 7 by signing an annual purchase contract with the latter.

Increasing construction of steel-structured buildings is an effective way to reduce construction waste and protect the environment. It also has the value of being a strategic reserve.

To address the current overcapacity situation in the domestic steel industry, the State Council, China's cabinet, issued guidance recently to address the problem by raising the percentage of steel structures in the building construction sector.

Contact the writer at dujuan@chinadaily.com.cn

(China Daily European Weekly 01/03/2014 page21)

Today's Top News

Merkel fractures pelvis skiing, cancels visits

Portugal declares three-day mourning for Eusebio

Forbidden City to be closed every Monday

Icebreaker prepares for breakout

Beijing rejects Abe's call

Illegal ivory stash destroyed

Israeli ex-PM Sharon's condition in steady decline

Yahoo says ads in Europe spread malware

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|