SMEs respond to pressures with ingenuity, new products

Updated: 2013-07-19 07:32

By Shi Jing and Yu Ran in Shanghai (China Daily)

|

|||||||||||

|

Workers inspect toys at a factory in Lianyungang, Jiangsu province. The manufacturing sector contributes about 40 percent to China's annual GDP, with 60 percent of it coming from SMEs. Si Wei / For China Daily |

There is a Chinese saying that goes something like this: Back against the wall, and survive.

Many small and medium-sized enterprises in the private sector are finding themselves in that situation. They have been pushed against the proverbial wall by rising costs, dwindling overseas orders and the relentless appreciation of the yuan, which are sapping their competitiveness and eroding their profit margins.

Many of them are fighting back with ingenuity, wit and help from the government. The many thousands of private-sector SMEs are facing quite similar issues. To overcome the labor shortage problem, they need to invest in new machinery. But securing loans from banks at reasonable interest rates is, as some have said, like drawing blood from a stone.

A major objective of the government-initiated financial reform is to channel liquidity to the real economy, represented to a large extent by the many private-sector manufacturing enterprises of all sizes. But the process is slow and old banking habits die hard.

"Our problem is money," said Ye Shuhui, sales manager of Ningbo Jinfan Toy Co. China has plentiful capital. But much of that has gone into property and financial products.

The problems of the manufacturers are forcefully reflected in the nation's two purchasing managers' indices, which signal the health of the economy.

The PMI from HSBC, which tracks the performance of private-sector SMEs, contracted in May and June.

One from the National Bureau of Statistics, in which large companies have a heavy weighting, retreated to a nine-month low of 48.2 in June. A reading below 50 indicates a contraction of economic activities while one above shows expansion.

Of course, the government is concerned. The manufacturing sector contributes about 40 percent to China's annual GDP, with 60 percent of it coming from SMEs.

There are more than 10 million SMEs in China, accounting for 95 percent of all companies, yielding 50 percent of China's tax income and 80 percent of the job openings.

Premier Li Keqiang said at a State Council meeting in April that SMEs should be given a fair chance compared with State-owned enterprises. He also reiterated the importance of accelerating economic restructuring via structural tax cuts, which will do much to help SMEs.

To solve the financial problems of SMEs, the State Council released a series of advisory measures on financial support for economic restructuring and upgrading on July 5.

"The launch of the 10-point program will help SMEs solve the problems of a lack of loans, with lower costs and more capital made available by decreasing the reserve ratio of banks," said Zhou Dewen, chairman of the Wenzhou SME Development Association.

Fu Jiarong, manager of the Wenzhou Jiexin Small-Sum Loan Co, said the company used to offer certain temporary support to maintain the cash flow of SMEs. Now, it sees more borrowers coming in more frequently for short-term loans.

Fu added that most of the SMEs need more financial support to face the slowdown and upgrade, which would be solved in an improved financial environment with lower costs.

Ningbo Jinfan Toy Co has been the exclusive Chinese manufacturer of stuffed animals for Starbucks Corp for more than a decade.

Although it managed to achieve 20 percent growth in the second quarter as demand from Starbucks grew, sales manager Ye Shuhui said it will hardly make any profit this year, given the soaring operating costs.

Earlier this year, Jinfan replaced half its 70 sewing machines with highly automated ones, as Ye believes that automation "is inevitable".

A new machine costs 4,000 yuan ($650), almost four times the price of the old machines. But the company can't find enough staff.

Older workers have returned to their hometowns and the younger generation is unwilling to pick up the skills. "As a result, only five of these automated machines are running now," said Ye.

The acute labor shortage has forced the company to raise wages to attract skilled workers. A worker who is highly proficient with operating these sewing machines is paid 6,000 yuan a month, much higher than managers.

"We are kind of falling into a dilemma. On one hand, we have to automate, but on the other, expensive machines cannot fully replace a human workforce, thus the surging cost," he said.

Ye added that SMEs are facing heavy tax burdens. "We seek little financial help now as bank loans are very limited for SMEs. But we do hope that taxes will be reduced somehow."

The central government began trying out a shift from the business tax to a value-added tax at the beginning of 2012. Some of the modern service companies in Shanghai, which were the first to enjoy the new policy, saw their tax bills fall by up to 40 percent.

Li Jianjiang registered a light company in Japan in 1993 and opened Zhejiang Teling Light Industry Co Ltd in Wenzhou as a production base in 1997. To expand the market, Li's company is now also making electric products such as shavers, hair cutters and massagers.

A sales department for small electric appliances was launched earlier this year, which aims to have more than 100 sales points in stores in China.

When the manufacturing industry in Wenzhou slowed down as a result of the global recession, Li started his own small-loan company as a side business.

The company offered loans of more than 1 billion yuan to hundreds of companies in 2012.

"I am discussing with my business partners about launching a private-invested bank to break the monopoly of State-owned banks, to lend to private companies with manageable risks," said Li.

Jin Feipeng, general manager of Shanghai Jiu Ding Clock, dared to transform his family business as an original equipment manufacturer of overseas clocks and clock replacements into one that is a designer and manufacturer of electric protective covers for automobiles.

"After working in the family company for more than two years, I realized that being an OEM shouldn't be the future of the company," said Jin, taking into consideration the declining domestic and foreign need for his company's luxury timepieces in the past three years.

Investing nearly 20 million yuan in his new business, Jin said they have already received more than 30,000 orders, mainly from domestic buyers.

The electric car cover, which can be charged via solar energy in five hours and with electric plug-ins in a shorter time, will go on sale in late July and is expected to bring in 10 million yuan in the first three months.

Jin added that he had the design team and technicians of the clock company complete part of the work for the new product as well as buy in parts from other smaller manufacturers to minimize the labor costs.

"I believe the market for electric protective covers for cars will be much larger with long-term expansion than the clock industry, which will be maintained as a smaller traditional sector," said Jin.

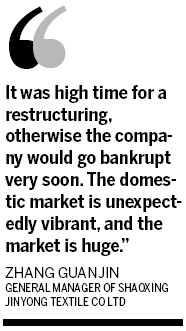

Noticing the shrinking export orders and tougher trade requirements from overseas, Zhang Guanjin, general manager of Shaoxing Jinyong Textile Co Ltd in Zhejiang, who has been in the textile industry for more than 25 years, turned back to the domestic market at a time when the central government is calling for boosting domestic demand.

Jinyong used to be a highly export-oriented company, with more than 90 percent of its products sold overseas. But it started to look inward in 2008. Zhang saw "it was high time for a restructuring, otherwise the company would go bankrupt very soon".

Starting this year, Zhang's company is selling 60 percent of its products in China and the rest overseas. Even though export orders decreased by 20 percent, the company is still doing quite well. "The domestic market is unexpectedly vibrant, and the market is huge," he said.

What is also a great surprise to Zhang is that Chinese customers have higher requirements for creativity and innovation. His company is now not only manufacturing but also designing.

"As an export-oriented company, we used to care about the amount only. But now, we are designers, and it is the major task we have to complete," said Zhang proudly.

Contact the writers at shijing@chinadaily.com.cn and yuran@chinadaily.com.cn

(China Daily 07/19/2013 page17)

Today's Top News

China's government spends less in 2012

Obama weighs canceling Moscow talks with Putin

Xi hails closer cooperation with Switzerland

Yuan: Collateral types to expand

Overall home price rise softens

'Downside risk can be managed'

Detroit files biggest ever US municipal bankruptcy

Mandela turns 95 in hospital bed

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|