Moving not only answer for textiles

Updated: 2014-12-05 11:21

By Wang Chao(China Daily Europe)

|

|||||||||||

Despite the rush to transfer China's factories to lower-wage locales, some say there are other options

With the average wage of the 23 million textile workers in China reaching $600 (488 euros) a month, garment factory owners are starting to greet each other with a variation of: "Have you moved the factory out of China yet?"

But some industry leaders do not think China's textile industry has approached its sunset, and instead of retreating from China they plan major expansions.

Esquel Group, a Hong Kong-based garment-maker, plans to invest 2 billion yuan ($325 million; 261 million euros) to build a new factory in Guilin, Guangxi Zhuang autonomous region.

Established in 1978, Esquel is a textile conglomerate running a complete value chain of cotton growing spinning, weaving, dyeing, sewing, and retailing. It is the largest cotton shirt maker in the world in terms of output.

Last year it made more than 100 million shirts for different brands across the world, with total turnover of $1.3 billion. Every second, eight shirts can be produced in an Esquel factory.

John Cheh, vice-chairman and CEO of Esquel, says it is not necessarily a bad thing that wages keep rising in China. "Rising wages means improved skills, higher efficiency and improved consumption power among Chinese people.

"There are good opportunities overseas, but the low labor cost won't be the only consideration. Because the labor cost in these cheap areas will eventually rise, then we will lose competitiveness eventually; so moving is not a wise solution."

However, the labor cost is not the only challenge, says Wang Tiankai, director of the China National Textile and Apparel Council. Figures from the council show the momentum of China's textile industry has slowed significantly since 2011. From 2000 to 2010, average growth was 18.8 percent, but it fell to 12 percent in the past four years.

"The price of high-quality cotton in China is about 30 percent higher than the international level, which caused fiber processing in China to drop by 26 percent last year," Wang says.

"Meanwhile, the wage level is growing 10 percent a year. The level of the minimum wage is rising, and by only offering the minimum wage, you can never recruit a skilled worker."

Under these circumstances, many Chinese garment-makers have moved their factories to cheaper places such as Southeast Asia and Africa.

Unlike other Chinese garment-makers, Esquel set up factories overseas at the very beginning. Its first factory opened in Malaysia, and now it has factories there, in China, Mauritius, Sri Lanka and Vietnam.

"We never talk about moving out of China," says Aaron Lee, chief operating officer of Brands & Distribution, Esquel Group. Lee compares the Chinese textile industry with the car industry in Europe 20 years ago.

"By then everybody was talking about the car industry leaving Europe, as the cost was so high and the competition from Japan and South Korea was so fierce; but now it is still thriving in Europe. That tells us: It's not the cost but the margin that really matters.

"We are thinking more of optimizing the process and adding value than of chasing after cheap labor," Lee says.

Esquel makes only high-end shirts for international brands such as Zara, Ralph Lauren, Tommy Hilfiger, Nike and Muji, as well as some high-end domestic brands in China, so the margin is higher than in making simple T-shirts.

Marks & Spencer is among these major clients. Every year it buys more than $60 million in products from Esquel. Frazer Mead, head of innovation and quality, Far East region of Marks & Spencer, says although cost is a major concern, there are other considerations in assessing a supplier, such as whether the factory can deliver quality products, whether it can deliver on time, and whether it meets the sustainability requirements.

Mead says China is getting more expensive for making garments, but the company's business in China will stay relatively stable.

"China represents 60 percent of garments that M&S buys in Asia, and about 40 to 50 percent of the total in the world. In terms of fabric, China represents about 60 to 70 percent of the fabric we use across the world."

Chinese workers' skills and efficiency are so high that they are hard to replace, he says.

"My job is to assess countries' suitability for certain kinds of products," he says. "Simple products such as T-shirts, basic trousers and nightwear can be migrated more easily to lower-cost countries; but lower-cost countries generally mean lower skill levels. You have to be careful when you move to Bangladesh or Vietnam so you don't bring products to them for which they have yet to develop the skills."

Having sourced in China for nearly 30 years, Mead says the good thing about the country is that there is a lot of choice, and the challenge is to find the right people and to choose the right partner.

"China is a world leader in terms of raw materials such as fabric, especially linen, cashmere and silk. And the innovation is getting better, driven by the competition from South Korea," he says.

Over the years, China has also changed from a manufacturer of cheap garments to a major market for international brands.

Ten years ago, almost 100 percent of the garments made by Esquel were exported to Western countries, but now the ratio of products exported to the United States has dropped from 70 percent to 40 percent, says Cheh. "Now domestic clients account for more than 12 percent, from zero 10 years ago. Some are domestic brands, some are foreign brands buying directly from Esquel and selling them in the Chinese market under their brands."

The Chinese market is getting so dynamic that both brands and suppliers have to adapt to the change.

"In the UK, the typical age profile of M&S's customers is 50-plus. When people reach that age, they actually are proud of clothes that can last for a long time," Mead says. "But here we have to struggle with a balance between garments that people expect to last long and those people would like to wear for one season for pure fashion reasons.

"And with the burgeoning middle class and well-defined education system in China, not everybody wants to wear clothes with a big logo. People are looking for fashionable things, but also something that will last more than one wash," he says.

M&S has been retailing in the United Kingdom for 129 years, which tends to build trust for a brand through generations. "So children learn this brand from their parents or grandparents; but in China we have yet to achieve this penetration," Mead says.

The ever-changing taste of consumers means brands have to keep innovating by creating new designs and new functions, which raises new requirements for garment manufacturers.

Lee of Esquel says that every season the company calls a meeting to talk about new research and development and new designs, so its clients can come and decide which new elements and new functions they want to incorporate into the products.

"We are not just selling them shirts. As a garment-making factory, we have a lot of interaction with our clients. We do our part, such as R&D, design and merchandising to be supportive," Lee says.

Building a high-end brand is another way to raise the margin, experts say, but so far no Chinese company has succeeded in building an internationally renowned brand. Even Esquel is still at the very early stage of building its own premium shirt brand, Lee says.

He says the company has no intention of buying Italian or Spanish brands and publicizing their "European style", as some Chinese companies have done. It established a shirt brand called Pye, but so far it has only six stores. "We hope Pye becomes an international brand someday, but the current scale is small. If we want, we can open more stores very quickly so long as we inject enough money, but consumer recognition won't be gained as quickly."

The brand contributes only a fraction of Esquel's total revenue.

Wang of the textile council suggests companies innovate more with materials so they are able to come up with more functional materials. "They can then be less dependent on cotton," he says.

Esquel's new factory in Guilin will raise the proportion of technicians from the current 2 percent to more than 9 percent.

"Textiles is the only industry in which China has a strong advantage in the world, and we have good reasons to keep it alive," Wang says.

Zhong Nan contributed to the story.

wangchao@chinadaily.com.cn

|

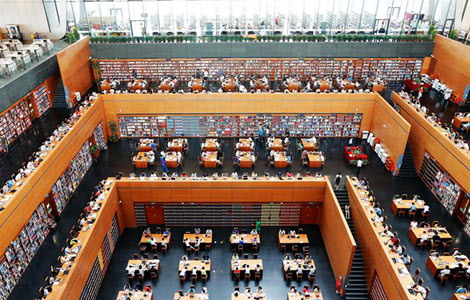

Workers in a textile factory. The momentum of China's textiles industry has slowed significantly since 2011. Wang Chao / China Daily |

|

Many Chinese garment-makers have moved their factories to cheaper places such as Southeast Asia due to rising labor costs. Provided to China Daily |

(China Daily European Weekly 12/05/2014 page14)

Today's Top News

China set to make tracks for Europe

Global net tightened in hunt for Chinese fugitives

Russians flock to stores to pre-empt price rises

Wong Kar-wai: Timeless director who makes time wait

China pledges $3b investment for Europe

Obama to sign Russia sanctions bill, White House says

Beijing condemns Pakistan school attack

Wolfsburg signs China midfielder for 2 1/2 years

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|