New-age outlook in age-old Hunan

Updated: 2013-12-20 10:05

By Joseph Catanzaro and Tracey Barrett (China Daily Europe)

|

|||||||||||

Industries and cities in the central China province connect around the Yangtze and Change course to sail strongly into future

The factory floor in Changsha reverberates with the thunderous rumble of mysterious machinery, relentless robotic arms turning out enough building material every 72 hours to make an entire skyscraper. Somewhere in Russia, and in parts of Africa and South America, the pieces of prefabricated concrete wall the factory spits out will become offices and homes.

In a cavernous workshop in Zhuzhou, technicians swarm over the carapaces of new electric trains, assembling and outfitting rigs that will ride the rails across China and other lands.

On the floor of a warehouse in Xiangtan, giant wind turbines wait. Already the engines of a greener China, from next year, they will claw at French skies and power their homes.

In a processing plant in Changde, men and women in white coats oversee a river of rice products that will feed people in Europe and South-East Asia.

And on the docks in Yueyang, men with weathered faces load ships that will take goods down the Yangtze River to Shanghai and across the sea.

These five cities, linked to each other and increasingly connected to all corners of the globe, are located in one Chinese province. This is Hunan, where pieces of your world are made every day.

Rich in ancient and modern history, Hunan is home to a group of prominent figures who went on to change and shape China, Mao Zedong foremost among them. But while citizens, leaders and industry kingpins are proud of their region's past, all eyes are now on Hunan's future.

Change and innovation are taking shape behind the often-closed doors of the region's big businesses, presenting opportunity and competition alike for the rest of China and the world.

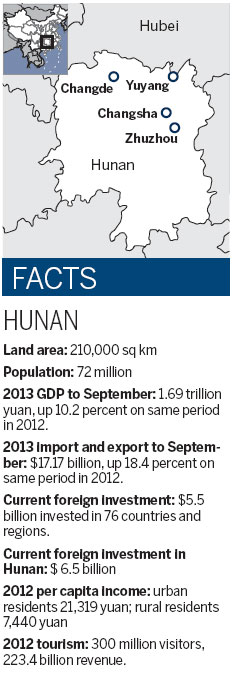

Located in China's sub-tropical monsoon zone along the middle reaches of the Yangtze River, boasting a population of about 72 million, Hunan has one of the most dynamic economies in the central and western regions. Last year, its GDP of more than 2.2 trillion yuan ($362 billion; 263 billion euros) and average growth rate of 13.3 percent placed it in China's top 10 performing provinces for the fifth consecutive year.

Xie Jianhui, director-general of the Hunan Commerce Department, says between January and September this year, the province's GDP reached 1.69 trillion yuan, a year-on-year growth of 10.2 percent.

But China, and the world, is changing. While Hunan is an economic powerhouse, local officials realize they have to change with the times, or face being left behind. Xie says as a result of this forward-looking mentality, Hunan is increasing becoming a global trader with bilateral investment links to a range of countries.

During the first three quarters of this year, Hunan's total volume of import and export reached $17.17 billion, she says. "With a year-on-year growth of 18.4 percent, the growth rate (in import and export) ranks first in central China."

Europe is fast becoming a key location for Hunan's outbound investment, Xie says, 81 enterprises in the province have invested a total of $733 million in the EU.

But the lion's share of the province's total foreign investment still goes to Asia.

"We have 529 enterprises which have invested in the Asian region, accounting for more than 60 percent of all the enterprises in Hunan that have invested overseas," she says. "The total contracted investment has now reached $4.02 billion. The major countries and regions that our enterprises have invested in are Hong Kong, Laos, Vietnam, and Thailand.

Conversely, foreign investment in Hunan is also being encouraged by the provincial government's move to cut red tape.

"There are 131 enterprises of the Fortune 500 enterprises in Hunan, including Fiat, Mitsubishi, BYD Auto, VW, Siemens, and Honeywell," Xie says. "From January to September, the utilization of foreign capital reached $6.5 billion, with year-on-year growth of 19.1 percent. We have undertaken 2,518 industrial transfer projects, among which 309 are international projects."

Between January and September this year, Xie says 351 Asian investment-backed projects went ahead in Hunan, representing almost 86 percent of all foreign investment.

The vice-governor of Hunan, Chen Zhaoxiong, says the current economic condition of the province "provides a solid foundation for future development".

Much of the success is attributed to a plan that was set in motion about six years ago. At the end of 2007, the State Council approved a blueprint to develop three Hunan cities - Changsha, Zhuzhou and Xiangtan - into a pilot zone for building a resource-saving and environmentally friendly society.

The plan, called the "two-oriented society", was later expanded to include another five cities - Changde, Yiyang, Yueyang, Loudi and Hengyang all within an hour and a half drive of Changsha, Zhuzhou or Xiangtan.

The interconnectivity of the cities, and their ability to share resources and reduce redundancies, has been the lynchpin of a series of changes and reforms in the province that have enabled the market to begin to drive ahead and innovate. More than 80 industrial zones and parks with varying incentives and favorable taxation conditions have further stimulated growth.

"We are restructuring our economy and increasing the role played by creativity and innovation in our economic growth," Chen says. "We are establishing a modern industrial system."

On the floor of a factory in Changsha, the founder and CEO of Hunan Farsoon High-Tech Co proudly shows off a futuristic-looking machine that epitomizes the kind of innovation Chen is keen to see more of.

Established in 2009 by Dr Xu Xiaoshu, Farsoon is now China's biggest and the world's third-largest manufacturer of selective laser sintering equipment, the technology driving the 3D printing industry that many have heralded as the dawn of a new industrial revolution.

"Our company does not make products; our company makes the machines and the materials," Xu says.

He says business is booming and Farsoon is expanding to keep pace.

"We currently have limited capacity to make products - four at a time," he says. "We move to a new facility next year and will be able to make 40 at a time."

The company's own formula of SLS Nylon powder, which its machines can turn into anything from moving car parts to prototypes for prosthetics, has been exported to overseas markets including the US, Sweden and Italy since last year.

Next year, the machines will be available for sale overseas, too. At present the roaring demand in China coupled with limited production capacity means each of Farsoon's machines are sold for more than 1 million yuan.

With the US pushing hard to maintain an edge on what is tipped to be a technology capable of revolutionizing the manufacturing and medical prosthetics industries, Xu says his work is vital to China.

"Metal, ceramics, all of these materials are in research (for use in 3D printing) right now," he says. "We have already made some metal parts. If we want to keep manufacturing jobs in China, we need to improve technology. This technology will replace traditional industry in the long run. In theory, you can use it to make a car or a plane. But at the moment it's too expensive. We invest a lot in research and development."

Down the road at Broad Homes, CEO Fen Tang says its automated lines are pumping out pre-fabricated walls that are fast becoming the building blocks of a greener China and a cleaner world.

"We are a link between traditional and new sectors," she says, touting the environmental credentials of the company's product.

The construction industry accounts for one third of all waste generated in Chinese cities, Broad Homes says. In comparison to traditional construction, the company says its process requires 80 percent less water. The insulation quality of the finished product also generates a 70 percent energy saving over the lifetime of its buildings.

With nine manufacturing bases across China and a new factory being built in South America, Fen says by 2015 the Hunan heavyweights will have a 5 percent market share of the Chinese construction industry and will continue to expand overseas operations in regions such as Russia, Africa and the Middle East.

In Zhuzhou city, at the CSR Zhuzhou Electric Locomotive Company, spokesman Zhang Jiajie says research is firmly on track for the future of commuter transport. The company, which has cornered half of the Chinese market and exports to a host of countries in central Asia and beyond, is testing a new experimental train.

Similar to the Maglev train in Shanghai, the CSR prototype uses magnet technology and is expected to be ready for sale and use in 2015.

"It's still in the experimental phase," Zhang says. The key environmental benefit is the train's low energy consumption, he says.

In the Xiangtan assembly workshop of Asia's biggest pharmaceutical machinery manufacturer, Truking Technology, Argentinean Alejandro Perez and his colleagues run new equipment through its paces.

Impressed, the group decides to buy a number of devices for commercial use in South America. Ten years ago, Perez says they probably would have purchased the equipment from Europe. But after having just made a similar trip to the EU to explore the cost and quality there, Perez confidently says Truking now trumps the competition in price and is competitive in performance.

"It's much more expensive there in Europe, about $1 million to $2 million," Perez says, pointing at a complex piece of pharmaceutical manufacturing machinery. "It's about $700,000 here in China. And the quality is good - we checked."

The South Americans aren't the only ones shifting their custom from the EU to China. Truking already exports to more than 20 countries, and has even bigger plans for the future.

"By 2020 we would like to be ranked first in the world in this industry," says company vice-president Zhou Feyue.

Of Truking's 2 billion yuan in annual revenue, Zhou says about 5 million yuan is pumped back into research and development. It is part of a longer-term strategy that aims to use innovation as a ladder Truking can climb to reach the top of the global market. Experts from India, Belgium and Pakistan are already on the company payroll, and there are plans to open a third research center in Europe.

Across the other side of Xiangtan, Geely, one of China's major automotive manufacturers, is gearing up to break into the hybrid and fully electric vehicles market.

Another company, Xiangtan Electric Manufacturing Group, has put more than 2,000 2-megawatt wind turbines on the market since 2008 and is testing a 5 mW prototype. A deal to export product to France is in the works.

While the new and the innovative are rising fast to join stalwarts like steel and iron and petrochemicals among Hunan's pillar industries, the oldest trade in the province still looms large.

In 1998, archeologists working in Hunan unearthed rice husks more than 6,500 years old. The discovery, confirmed as the world's oldest known rice paddy, suggests the province is the cradle of global rice cultivation.

Hunan remains China's rice bowl, today. Jinjian Cereals Co in Changde, which has cornered 85 percent of the market in all major Chinese cities, and exports products to countries across Asia and Europe, is now combining space-age technology with ancient agriculture.

Company president Lu Qisong says specially developed hybrid rice strains have changed the industry. Where normal rice yields about 600 kilograms per 667 square meters, the hybrid strain is capable of much more.

"If it's hybrid rice, we grow more than one ton per 667 sq m," he says.

Jinjian is also experimenting with a system that will allow it to burn off discarded husks, and use the subsequent heat to generate electricity.

Hunan Commerce Department chief Xie is optimistic about the province's future. While the path ahead presents many challenges, she says economically at least, the province's regional and global links mean it will not be walking alone. And prosperity, she says, is a two-way street.

"In this open world and open economy, we have to cooperate with each other so that we can achieve common prosperity."

Contact the writers through josephcatanzaro@chinadaily.com.cn

|

Newly produced locomotives of CSR Zhuzhou Electric Locomotive Company. Wang Jing / China Daily |

(China Daily European Weekly 12/20/2013 page20)

Today's Top News

Chinese merchant killed during robbery in Russia

IPR courts 'would be helpful'

Liaoning's combat capability tested

GM corn rejection not to hurt market

US aircraft hit by gunfire in South Sudan

Memorials mark Lockerbie attack

H5N2 outbreak confirmed in N China

China's moon rover works stably

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|