How costs stole Christmas

Updated: 2010-12-24 10:53

By Gao Qihui and Li Wenfang (China Daily European Weekly)

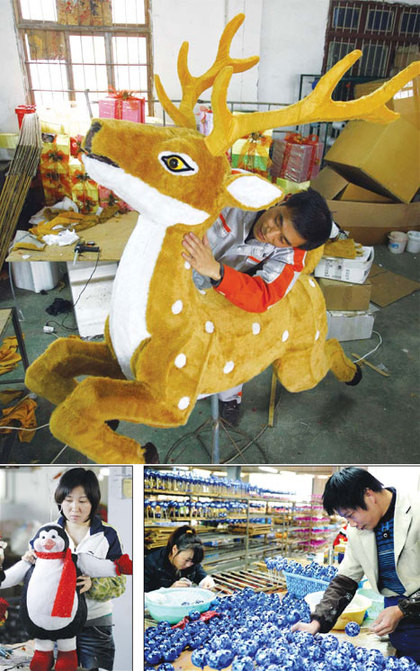

Problems with labor and materials push Chinese producers of festive goods to the brink

Christmas is "the most wonderful time of the year", sings crooner Andy Williams in his 1963 hit. Many Chinese manufacturers used to agree - not any more. After a year of coping with labor shortages, price hikes for raw materials and an appreciation of the yuan, many companies that make yuletide products are now considering pulling out of the industry. Almost 60 percent of the world's Christmas products come from China. Yet, while toymakers record healthy profits, factories producing decorations and ornaments say they are struggling.

"If the situation does not improve, we'll definitely want to quit (production)," says Cai Qichang, owner of an arts and crafts company in Shantou, Guangdong province. "The sun is setting on the Christmas product industry (in China) right now."

Exports of festive products from the province actually hit $770 million (586 million euros) between January and October 2010, a 3.9-percent year-on-year rise, according to official data.

Roughly 48 percent of all Christmas products exported by China in the first 10 months of this year were made in Guangdong.

Christmas-related exports from Guangdong to the United States and the European Union, which took up 78 percent of the total, grew by 5.9 percent and 7.3 percent to $410 million and $190 million, respectively, in the first 10 months of this year, according to Guangdong Customs.

However, the increase has failed to ensure a merry Christmas for producers.

"Orders for our hand-crafted Christmas ornaments, dolls and other works did increase slightly this year," says Huang Shaokuang, sales manager at Jiaying Arts and Crafts in Shantou's northern Chenghai district, which is home to more than 3,000 producers.

Yet, despite generating almost 8 million yuan (915,600 euros) in sales, as of October, the company had made no profit.

"Still, we have fulfilled our social duty of feeding our workforce of more than 80 people," says Huang, forcing a smile.

Factories across Chenghai have reported similar experiences, with "many actually running at a loss", adds Cai, who is also chairman of the Chenghai Arts and Crafts Association, which is made up of more than 100 small and medium-sized enterprises.

Rising expenses

Profit margins for factories making Christmas products are already paper-thin, ranging from just 2 to 5 percent, according to a recent report by Xinhua News Agency that quoted an unnamed expert with the Chinese Chamber of Commerce for Imports and Exports of Light Industrial Products and Arts and Crafts.

Things have only been made worse by sharp rises in the cost of labor and raw materials.

Wangda Toys Co in Shantou suffered a 10 percent rise in raw materials, 15 percent hike in workers' pay and a stronger yuan, says its sales manager Wang Junwei.

|

The prices of non-woven fabric, the most common material used in festive ornaments and dolls, soared from about 8,000 yuan a ton in January to more than 16,000 yuan a ton in October.

"With raw materials making up at least 40 percent of our gross costs, I dare not purchase any non-woven fabric right now. I'm waiting for the price to drop," says Huang, whose company has been producing yuletide ornaments for 18 years.

Yihua Hardware & Handicraft Co in Dongguan earned about 10 percent profit from a Christmas tree last year but almost no profit this year, says the head of the company surnamed Chen, reported the Dongguan Daily.

The price of polypropylene fiber, which is used to stuff many toys, has grown by about 20 percent so far this year, according to Taibai Fiber Co in Guangzhou.

The cotton price had climbed from about 18,000 yuan to 28,500 yuan per ton by mid-November since Sept 1, according to the statistics posted on industry website Cottonchina.org.

Many traders are now looking to buy from manufacturers in East China's Zhejiang province, where supplies are cheaper.

"We're now less competitive, as Shantou is not a source of raw materials," complains Chen Shaoyan, owner of Zheng Chang Long Carton Factory, which has been making yuletide ornaments for 10 years.

However, even in Zhejiang, the so-called "home of fabrics", plants have witnessed staggering price hikes for core material in their products.

"Our gross costs have increased by about 25 percent," says Huang Jili, general manager of Orient Crafts in Ningbo, a city on the province's east coast. "We are feeling the same pressures."

Although the price of raw materials is likely to fall, analysts predict companies will have to deal with labor shortages and rising salary demands for some time to come.

Factories across the Yangtze River and Pearl River deltas - China's two economic powerhouses - have been short on hands since March this year, following the national Spring Festival holidays.

In response, at least 14 provinces and municipalities have raised the minimum wage, including both Guangdong and Zhejiang.

"If my production line is running at a full capability, we need at least 800 workers," says Chen in Shantou. "This year, I had only 200 workers during the peak time."

He says the situation forced his company to reject several orders from clients, resulting in sales falling 30 percent.

"Some manufacturers finished the orders at a loss to maintain the operation and keep their workers," adds Chen.

Luo Yonghuang, deputy general manager of Hongfeng Arts and Crafts in Meizhou, Guangdong, complains that even though he raised his workers' wages by 150 percent, the company still experienced a labor shortage.

As most Christmas products are assembled by hand, the industry is extremely reliant on human resources, and a shift toward mechanized operations would be economically unfeasible for most.

E-paper

Ear We Go

China and the world set to embrace the merciful, peaceful year of rabbit

Preview of the coming issue

Carrefour finds the going tough in China

Maid to Order

Specials

Mysteries written in blood

Historical records and Caucasian features of locals suggest link with Roman Empire.

Winning Charm

Coastal Yantai banks on little things that matter to grow

New rules to hit property market

The State Council launched a new round of measures to rein in property prices.