Stepping up

Updated: 2015-09-11 07:27

By Andrew Moody(China Daily Europe)

|

|||||||||||

"When I go and see customers in Europe or the US, I say that although we are located in China we are not a typical Chinese low-price company," he says.

Liu says he has to go to considerable lengths to overcome this perception of Chinese manufacturing being associated with low-end technology.

"I ask them whether they have any new projects and say that we are willing to support and help them for free at the initial stage. I tell them they have nothing to lose since they can still work with our competitors in the US and Europe who will be charging them a development fee. We then prove we can produce a prototype within three months that is sometimes better or at least as good as our rivals. This is the way we have to work."

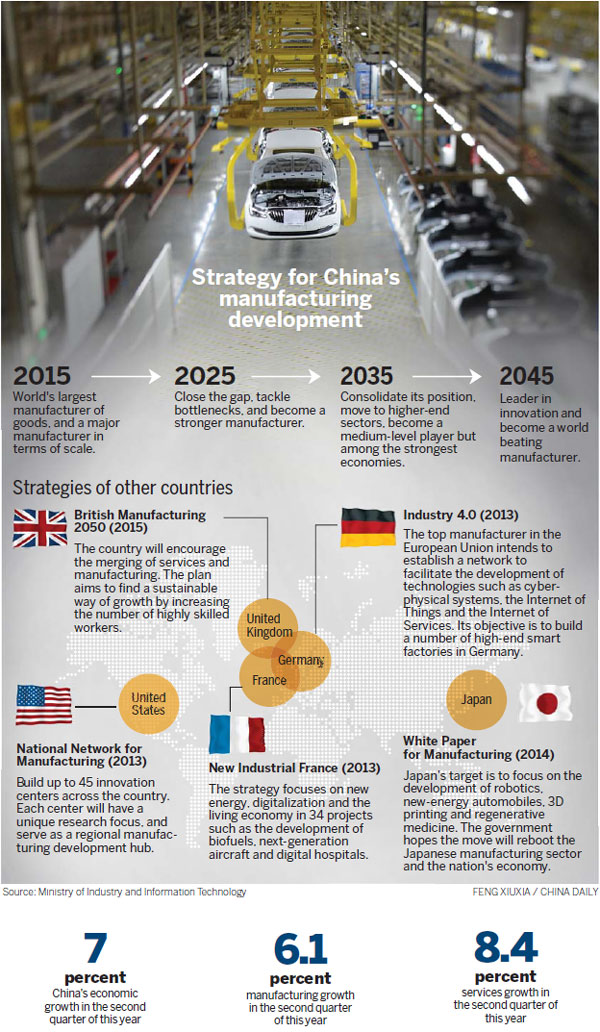

One of the aims of the 2025 strategy is to address weaknesses in research and development, product quality, dependence on low-end production, information technology and an inability to connect with global production and supply chains.

The strategy seeks to address certain key "bottlenecks", which the government says are hampering China's economic development.

For example, China spent $220 billion (197 billion euros) last year importing integrated circuits, more than it spent buying oil around the world. The aim is for China to make such products itself.

Wu Changqi, professor of strategic management at Guanghua School of Management, insists that whether the strategy is successful will depend on how it is implemented.

"I think it is important that it is not completely a top-down approach and also involves a lot of market mechanisms. It should not just be an industrial policy offering cheap bank loans and grants to companies working in particular sectors."

Wu says it is also important to maintain competition and not just protect domestic producers.

"If you want to promote electric cars, for example, you need to have a level playing field between Chinese and foreign companies. It is no good giving a subsidy of 50,000 yuan to a Chinese manufacturer for every electric car it makes. It is better to give it to the consumer so they can choose the best electric car on the market."

Shaun Breslin, professor of politics and international studies at Warwick University in the UK, says debates in China about moving up the manufacturing value chain date back to the 1980s.

"I don't think it is a matter of just saying it, you have to put a whole lot of other things in place so that innovation can actually happen. This brings up a whole series of thorny questions that go directly back to the education system and whether it allows sufficient freedom of thinking to create genuine innovation."

Despite the renewed focus on manufacturing, the sector is no longer the main driver of the economy.

It grew by only 6.1 percent in the second quarter of this year, down from 6.4 percent in the first quarter, and slower than the overall rate of economic growth of 7 percent.

Meanwhile, services - which already comprise a larger proportion of GDP than manufacturing - grew by 8.4 percent in the second quarter, up from 7.9 percent in the first.

It brings into question whether China should follow the UK and US model where services are around 80 percent of the overall economy or the German one, where manufacturing remains the key driver.

Shi Yongjiang, research director of the Centre for International Manufacturing at Cambridge University, says this is a more complex question than many assume because there is an increased blurring between what can be defined as manufacturing and what a service industry.

"If you take Rolls Royce, the aero-engine maker, for example, around half of its profits come from leasing its engines to airlines and providing the finance for that. So is this a service or is it manufacturing? You have this definitional problem everywhere now."

For William Kirby, T.M. Chang Professor of China Studies at Harvard University, regardless of these definitions, the role model for China has to be Germany.

"Who would not want to be like Germany? Even with a relatively high-cost base, it manages to maintain its manufacturing advantage extraordinarily well. It has an excellent school system that places emphasis on vocational training and has built a real strong base in this sector. As a result, Germany has managed to hang onto industries the US has just failed to."

Today's Top News

US to accept 10,000 Syrian refugees

China, Arab States to explore cooperation

Greek conservative to seek pact with leftists first if he wins election

Russian military experts present in Syria

Britain calls for talks to calm Northern Ireland crisis

Hungarian TV journalist fired for tripping up fleeing migrants

Inside look at new products launched by Apple

Economy will not see a hard landing: Premier Li

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|