Plugging into the European market

White goods manufacturer has gradually increased its presence and won customers for its products

Inside the Chinese white goods maker Changhong's spacious and highly automated factory in Nymburk, a city 45 km east of Prague, around 300 local workers are busy assembling TV sets.

These will then be shipped to countries including Germany, France, Spain, Italy and Switzerland.

The factory, which opened in 2007, was the company's first step into Europe. Changhong now makes 1 million TVs at the factory.

|

A worker assembles a television in Changhong's Czech Republic factory. Photos by Cecily Liu / China Daily |

|

Changhong's factory in the Czech Republic. |

Over the past decade, Changhong has worked hard to gain the acceptance of European customers, which was not an easy task - especially as "Made in China" to some European customers still means cheap products.

"To change this branding perception, we stress to our customers that our products are 'made in the EU and serviced in the EU'," says Huang Dawen, deputy general manager of Changhong.

To supply competitive customer service, Changhong focuses on providing fast responses and efficient solutions at its customer service center in Prague - "so that our customers can really see us as a local brand", says Huang.

In 2007 when Changhong started production in the Czech Republic, it made only 100,000 TVs a year, almost all of them for European brands. Today, the number of such orders has fallen to just over half of Changhong's entire production of 1 million sets.

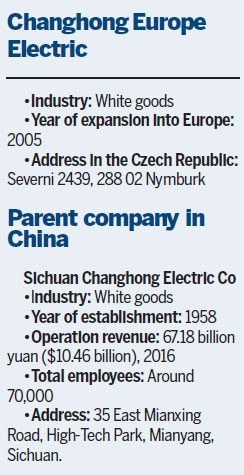

Sichuan Changhong Electric Co was founded in Mianyang, in China's Sichuan province, in 1958 as a State-owned maker of white goods such as televisions, air conditioners, refrigerators and other home appliances.

Over the years it has grown significantly, with revenue reaching 67.18 billion yuan ($10.46 billion; 8.57 billion euros; £7.56 billion) in 2016, and employee numbers totaling around 70,000.

Changhong has established 14 overseas subsidiaries and three overseas research and development centers. It employs 2,000 overseas workers, of whom 80 percent are locally hired. Its products reach more than 120 countries and regions.

In 1994, Changhong was listed on the Shanghai Stock Exchange. In 2015, it was ranked by the New York-based World Brand Laboratory as one of the World's Top 500 Brands.

Changhong first started thinking of expanding overseas in 1988. "At the time, we realized that China's domestic white goods market was reaching saturation. We realized there was still lots of market capacity overseas, and the low manufacturing costs of China gave us an advantage," Huang says.

Changhong's strategy was shared by many other Chinese white goods brands, which all ventured overseas around the same time, including Haier and TCL. Haier established a US subsidiary in 1999, focusing on selling cheap and small refrigerators to students. TCL, on the other hand, decided to expand through acquisition, buying Germany's Schneider Electronics AG in 2002 and France's Thomson TV business in 2003.

Changhong made its first overseas steps by setting up a television factory in Indonesia in 2000. "We decided to begin internationalization in a market close to home, where export transportation costs are lower and the consumer habits are similar to those of Chinese consumers," Huang says.

By 2001, Changhong celebrated its milestone of achieving revenue exceeding $100 million in Indonesia. In 2002, it established an additional assembly plant for air conditioners in Indonesia.

After these successful experiences, Changhong started expansion into Europe by setting up its subsidiary Changhong Europe Electric in the Czech Republic in 2005. It bought 110,000 square meters of land in Nymburk and in 2006 built a television factory.

One significant factor prompting Changhong to establish its European factory was the high tax the European Union imposed on imports.

Before 2000, EU anti-dumping rules imposed tariffs of about 40 percent on imported TVs, which would cut away most of Changhong's profit margin. The EU later moved to a system of quotas on TV imports, amounting to between 20 million and 30 million television sets from around the world, of which about 400,000 were allocated to China. But this quota was still too small compared to Changhong's ambitions in the EU.

To avoid these tariffs and quotas, Changhong established its Nymburk factory. "We chose the Czech Republic because its central location is convenient when transporting products to other European markets. We also felt that the Czech Republic has a highly skilled manufacturing workforce, and the labor costs there are quite reasonable," Huang says.

While capacity was building up at its Nymburk television factory, Changhong also focused on increasing sales of its refrigerators and compressors in Europe.

It currently sells around 2 million refrigerators in Europe, most of which are made for international brands. These refrigerators are manufactured in China and sold in Europe through the international brands' own channels.

"Unlike televisions, refrigerator exports to Europe are not subject to high tax. Therefore we decided to continue to manufacture the refrigerators in China," Huang says.

In its next phase of expansion, Changhong will look to export its own branded refrigerators to Europe, once they reach cutting-edge quality, Huang says. To achieve this goal, Changhong will focus on research and development to create well designed, highly efficient refrigerators.

Changhong's compressor business in Europe was largely built up through an acquisition it made in 2012 of the Barcelona-based company Cubigel.

The compressor is the most important component of a refrigerator, helping to create and maintain the desired temperature. The compressors that Changhong makes in Europe are mostly sold to European refrigerator makers, such as Germany's Bosch.

"We'd been looking for European compressor acquisition targets for a few years before we came across Cubigel through a lucky coincidence. At the time, Cubigel was entering into administration, so Changhong made the acquisition at a favorable cost," says Huang.

Changhong bought Cubigel for 2.6 million euros (£2.29 million) but, according to Changhong's estimates, Cubigel's fixed assets were worth around 20 million euros and the company's intangible assets had a value of around 5 million euros. The term "intangible assets" normally refers to values that are not physical, such as brand awareness.

After the acquisition, Changhong streamlined the Spanish plant's assembly processes and introduced new management techniques from its China factory.

For example, it introduced a new policy to systematically check, maintain and repair the factory's machines in August, a time when most European workers are on holiday, meaning the factory is generally not in operation.

"Due to our new policy, we are able to get our machines all set for full-scale production in September, when the factory is in operation again. Crucially, the machines' breakdown chances during busy periods are significantly reduced because of the maintenance work we've done," says Huang.

Changhong coordinated with its employees so a small team of employees would remain in the factory to carry out the repair and maintenance work during August, and take their holiday in September instead.

"We have managed to keep our employees happy, too, because under this arrangement they can go on holiday at a quieter period, when the cost of travel is also cheaper," Huang added.

Cubigel's production capacity grew from around 600,000 to 700,000 compressors a year in 2012 to 1.5 million in 2016. Over the same period, the number of employees fell from 650 to around 400, reflecting increased efficiency.

Looking to the future, Huang says Changhong will further build on the solid foundation it has already achieved in Europe for its televisions, refrigerators and compressors.

"We will focus on building up strong local teams, and increasingly improve our products to suit the needs of European local customers," says Huang.

cecily.liu@mail.chinadailyuk.com

(China Daily European Weekly 01/26/2018 page30)