Dyson's eyes on Chinese markets

Updated: 2013-03-15 09:03

By Wu Yiyao (China Daily)

|

|||||||||||

|

An electrical appliance store in Shenyang, Liaoning province. Demand for high-end household electrical appliances has boomed in China. Hong Yi / for China Daily |

Innovator hopes to capitalize on growing demand for high-tech electrical appliances

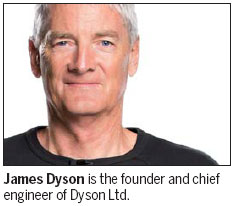

It has been more than 40 years since James Dyson, the British inventor and engineer, launched his first home appliance product, a cyclonic vacuum cleaner that would not lose suction as it picked up dirt.

Since then, Dyson, the founder and chief engineer of Dyson Ltd, has progressed from being a young man full of new ideas at the Royal College of Art in London to a knighted entrepreneur leading a company with some 4,000 employers, including 1,536 scientists and engineers.

Dyson Ltd sells some 85 percent of its products outside the United Kingdom - in more than 50 countries and regions. In 2011 the company's annual revenue for the first time exceeded 10 billion yuan ($1.59 billion; 1.24 billion euros). In late 2012, Dyson Ltd's products, which can be found at Buckingham Palace, the Tower of London, the Vatican, Harvard University and the Time Warner Center in New York, were launched in China.

"I look forward to bringing more machines to China in 2013," says Dyson.

Dyson Ltd's latest technologies include hot and cool fans, new cylinder vacuum cleaners and the digital slim cordless vacuum cleaner. In China, one of the company's most widely known product series is the Air Amplifier - the original bladeless fan.

Mutual embrace

Over the past two years, demand for high-end household electrical appliances has boomed in China despite slowing economic growth, according to a report by China Household Electrical Appliances Association. It also said that shrinking consumption of electrical appliances in general has polarized the high-end and low-end markets.

Sales of vacuum cleaners with prices higher than 1,999 yuan saw a 55 percent year-on-year increase in China last November, while those with prices lower than 299 yuan decreased by 39 percent, a GFK China report said.

People's desire for well-designed, fun-to-operate appliances with fashionable looks is growing fast. Over the past 12 months, middle and high-end household appliances developed at a high speed, yet there is still great potential for growth. As international high-end brands enter Chinese market and perform well, high-end household electrical appliances will also boom over the next few years, the GFK China report said.

The Chinese have embraced Dyson's appliances, the company says. They have high expectations of the technology Dyson Ltd uses, says Dyson. So far, the company has stores in Beijing and Shanghai, where the residents with most purchasing power in the country live.

"There seems to be a real appetite for technology. We brought our newest machines to China for their launch: digital handheld cordless vacuum cleaners, bladeless fans and our most advanced cyclone technology that doesn't lose suction," says Dyson.

To him, the difference between the Chinese market and that of the rest of the world is scale and variety, which makes it logistically challenging. But in terms of high-tech appliances, tastes are aligning globally, says Dyson.

"In the past we have designed smaller machines specifically for the Asian market. Now we are finding that the world over people want compact technology without compromising performance. This shift has been central to the growing popularity of our digital cordless vacuum cleaners and we look forward to seeing that growth continue," says Dyson.

Make-and-break cycle

To win in a market with fierce competition and a high potential for growth, engineers at Dyson Ltd have a focus - they tackle the problems that others ignore. Intensive investment is made to improve and to perfect products and to invent new things.

The career path of Dyson gradually adjusted until he found his real interest, too. He earned a place to study art at the Byam Shaw Art School in London, now part of Central Saint Martins College of Art and Design, where he found himself increasingly drawn away from art toward design. Next stop was the Royal College of Art where he took the leap from furniture design to industrial design - working with plastic and stainless steel to design solutions to everyday frustrations. And so began a lifelong passion for functional design.

His work is usually inspired from observing of existing instruments, including "reinventing the wheel", as he did with the Ballbarrow and the vacuum cleaner.

The wheelbarrow's metal predecessor hadn't changed for 2,000 years but James Dyson designed a smooth-edged plastic bin to replace it, which does not rust or allow fresh cement to stick to it. He also gave it more stability, replacing the wheel with a load-spreading red ball that stopped it sinking into soft ground.

His world-famous cyclone technology-based vacuum cleaner was inspired by a local sawmill. He noticed how the sawdust was removed from the air by large industrial cyclones. After 5,127 prototypes, he perfected and applied the technology working on the smaller scale Dyson DC01 vacuum cleaner. It finally began rolling off the production line in 1993. Within 18 months it was the biggest selling vacuum cleaner in the UK.

"Failure is the mother of invention," says Dyson. By the mid-1980s he was heavily in debt but he doggedly continued on his one-man licensing tour to promote his invention.

When he became well established as an inventor and engineer after the early, hard days, Dyson founded The James Dyson Foundation, a registered charity, in 2002. It was created to inspire the next generation of problem-solvers and support medical research charities, design technology and engineering educational work and community projects in and around Wiltshire.

"We are perfectionists and we invest 15 million yuan a week to make our technology the best it can be. Not only do we improve, we invent. We take old problems and develop new solutions - real solutions - to everyday problems, not gimmicks and imitations that simply look like they're doing the job," says Dyson.

Investing in innovation

To achieve continuous innovation, Dyson Ltd has spent more than 100 million pounds investing in a new compact digital motor. Spinning at 100,000 revolutions per minute, it is four times faster than a Formula One engine. "It's the brains behind our handheld vacuum cleaners and Airblade hand driers, giving high performance from a compact and efficient motor," says Dyson.

Dyson will put a significant proportion - 20 percent - of profits back into research and development in the next five years. The company has a pipeline of technology which stretches back 25 years. Many of the ideas are in their formative stages but research into new materials and their possible application is "exciting", says the founder. "It will allow us to create high performing technology and continually challenge ourselves to do more with less," says Dyson.

Since 1979, Dyson Ltd had gathered more than 1,900 patents worldwide from more than 3,500 applications and 1,000-plus registered designs worldwide from more than 1,200 registered design applications by 2012.

As a user of made-in-China and designed-in-China products, Dyson says China seems to be a pivot point.

"There is a growing awareness of and impatience with copycats. People are demanding better quality, well designed products from domestic and international companies," he says.

Before Dyson Ltd officially launched its products in China in 2011, many cheap copycats with labels including "Replica of Dyson" or "Dyson-style" were widely seen, especially on e-commerce platforms.

Dyson says a rigid intellectual property system is essential to protecting technology sold in China, both granting and enforcing patents.

"Great progress has been made by the courts in processing litigation but inventions and ideas need to be protected on the streets as well as in the courts. The investment in innovations is offset by the ability to protect our inventions and we do so determinedly," he says.

In 2012, the company spent 35 million yuan battling copycats, only to make a tiny fraction back in damages, according to its own figures. "This is money that could be re-invented into new jobs and developing new technology. As an inventor, I look at one of my machines and see all the time, money and effort that has gone into it. Infringers see a cheap win. We will continue to proactively protect our technology and be an advocate for ideas," says Dyson.

wuyiyao@chinadaily.com.cn

(China Daily 03/15/2013 page22)

Today's Top News

List of approved GM food clarified

ID checks for express deliveries in Guangdong

Govt to expand elderly care

University asks freshmen to sign suicide disclaimer

Tibet gears up for new climbing season

Media asked to promote Sino-Indian ties

Shots fired at Washington Navy Yard

Minimum growth rate set at 7%

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|