Siasun's metallic touch

Updated: 2012-10-05 08:53

By Zhong Nan and Wu Yong (China Daily)

|

|||||||||||

|

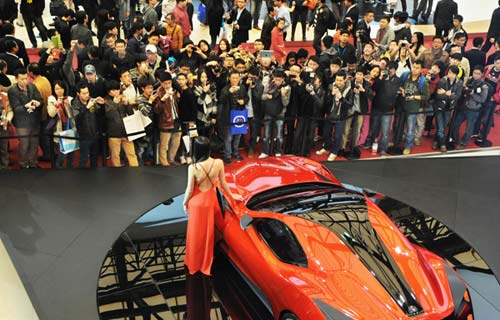

Siasun Robot & Automation Co Ltd is a beneficiary of an increasing use of robots by manufacturers in China due to rising labor costs. Provided to China Daily |

With labor shortages spreading across china, company expands production of industrial robots

One competitive Chinese company is looking to make up for the nation's intermittent labor shortages with workers that most likely will not complain or demand higher pay.

Siasun Robot & Automation Co Ltd, China's largest robot maker by market value, is seizing on the chance to help companies crippled by more expensive labor that has made China such a dominant force in the global economy. It is currently building two factories in Hangzhou and Shenyang, capitals of Zhejiang and Liaoning provinces, both of which are located on the nation's east coast.

|

The Shenyang-based robot maker sold 3,000 industrial robots in both China and to overseas markets last year, most to automotive companies. Total sales revenue reached 700 million yuan ($110.93 million, 85.91 million euros). Sales to the United States, Canada, France, Singapore and another nine countries accounted for 200 million yuan in sales last year.

Currently, the company operates seven factories that are involved in production as well as research and development in Shanghai, Beijing, Guangzhou, Shenzhen and three other Chinese cities.

With an investment of 200 million yuan, Siasun's Hangzhou project will be completed next year. Its Shenyang project is expected to be operational in 2013.

The number of Siasun employees is expected to increase from a current workforce of 1,500 to 4,000 by the end of 2015.

"Companies from Europe, Japan and the US once dominated the Chinese market, but imported robotic equipment often failed to fully meet the needs of Chinese factories, as the component and maintenance costs are too high," says Qu Daokui, Siasun president.

Founded in 2000, Siasun initially focused on producing industrial robots for China's fast-growing automobile market. A production line at an auto company with an annual capacity of 100,000 to 200,000 cars needs about 600 robots.

"In comparison with foreign-made robots, we have more knowledge about what our (Chinese) clients want and how to set up several programs for one production line operated by robots in their plants. It also costs less to send our engineers to different locations in China to solve (mechanical robot issues) within 24 hours," Qu says.

The average price for an industrial robot is about 200,000 yuan to 500,000 yuan. Some robots are pricier, such as the ones used in aircraft manufacturing, which can cost up to a million yuan.

Last year, Chinese companies bought more than 22,000 robotic products, with about 52 percent of them used in the automobile industry, according to the China Association of Automobile Manufacturers. Chinese carmakers such as Geely Automobile, BYD Auto and Great Wall Motors have equipped their factories with robots and increased the number of robots to improve efficiency in what is usually a grueling work environment.

"There is no need to become an expert to discover the quality gap between Chinese cars and vehicles made by foreign companies like Volkswagen, Audi or Toyota," Qu says. "Adopting better levels of equipment and technologies is the best way to compete."

The company's main automaker partners in China are Ford Motor Co, SAIC Motor, Brilliance Auto, Mazda Motor Corp and Dongfeng Motor Corp.

Siasun is investing 70 million yuan in research and development this year to provide advanced robotics to the automobile industry. The company is delivering 28 spot welding robots to China FAW Group Corp, one of China's top four automakers.

The company is also one of the suppliers of automated guided vehicles, a mobile robot that follows markers or wires on the floor, to Shanghai General Motors.

Most of the automated guided vehicles are powered by batteries and installed with security protection and auxiliary devices. They are commonly used in industrial applications to move materials around a manufacturing facility or a warehouse.

Siasun exported 42 automated guided vehicles robots to General Motors' headquarters in the US in 2010.

Siasun has also received a high volume of inquiries from traditional factories that are interested in robotic assistance, including clothing factories, shoemakers and electronics producers located in the Pearl River Delta, Yangtze River Delta and the Bohai Bay region.

"Robots never complain and ask for pay rises and factory owners can profit in several years. It is the trend that robots will replace a number of mechanic work positions over the next three years," says Ha Enjing, head of Siasun's branding and public relations department.

"We are also providing automated products and solutions to State-owned enterprises such as building automated power stations to charge electronic vehicles for the State Grid Corporation of China in Beijing, automated warehouses for China Shenhua Energy Co Ltd in Gansu and the Ningxia Hui autonomous region, and Daqing Oilfield Co Ltd in Heilongjiang province," she says.

In 2011, China invested about 10.3 trillion yuan to upgrade the manufacturing sector, up 31.8 percent from 2010, according to the National Bureau of Statistics. The majority of that spending resulted in newer and better factories.

"What you find is a high level of investment in Chinese manufacturing, but most of this is not going to expanding production capacities. It's making them more efficient and advanced," says Zhao Ying, a researcher at the Institute of Industrial Economics of the Chinese Academy of Social Sciences.

"Chinese robot makers should accelerate the speed of making breakthroughs in technology and concentrate the funds and human resources to develop key components such as actuators, sensors, hydraulic equipment and optimizing the production process to support industrial growth," Zhao says.

Zhao says Chinese companies need to understand that having the wherewithal to make robots is of itself not enough. Putting them to efficient and effective use depends on having qualified and skilled engineers thoroughly familiar with robot and systems integrations technology.

Contact the writers through zhongnan@chinadaily.com.cn

(China Daily 10/05/2012 page15)

Today's Top News

Rescuers race against time for quake victims

Telecom workers restore links

Coal mine blast kills 18 in Jilin

Intl scholarship puts China on the map

More bird flu patients discharged

Gold loses sheen, but still a safe bet

US 'turns blind eye to human rights'

Telecom workers restore links

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|