Breaking new ground

Updated: 2012-08-03 11:05

By Meng Jing (China Daily)

|

|||||||||||

|

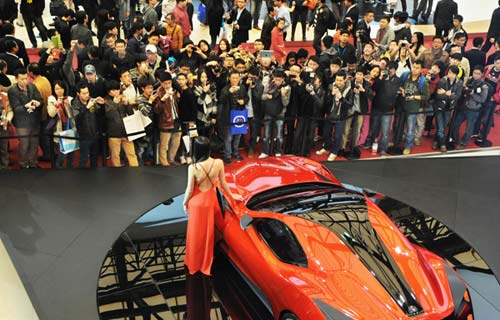

Shen Zhonghou, a member of the Chinese Academy of Engineering. Provided to China Daily |

Chinese scientists working on finding low-cost, green solutions for shale gas extraction

Despite the prospects of offering abundant natural gas with reduced carbon intensity, the shale gas industry still has a long way to go before it can build a green name for itself.

Much of that comes from the relatively unsafe and dangerous techniques that are currently in vogue for shale gas extraction around the world. Most of the current techniques are based on "fracking", a process by which natural gas is extracted from shale rock by blasting geological formations with a mixture of sand, water and chemicals.

Countries like Bulgaria and France have already imposed a ban on fracking, due to the extremely dangerous and volatile process. Environmental organizations from several countries including the US and Australia have also taken up cudgels against fracking due to its unsafe nature and the fact that it needs huge volumes of water, a commodity already in short supply.

Rather than challenge the rationale behind these moves, scientists in China are working on a technology that may not only have the answer to the safety concerns but also offers steady prospects of green energy from shale gas resources.

Shen Zhonghou, a member of the Chinese Academy of Engineering, an elite club of 767 top leaders in scientific innovation in China, says his team is working on technologies that use supercritical CO2, instead of the present fracking fluid, to extract natural gas from shale deposits.

"CO2 is colorless and harmless, but a major contributor to global warming. By using supercritical CO2 to extract shale gas, China can not only get more natural gas supplies but also cut back its greenhouse gas emission.

"Apart from the environmental reasons, China also needs to find its own techniques to exploit shale gas due to the unique nature of its geologic formation and water supply situation," says the 84-year-old Shen, often regarded as the father of the drill bit in China's oil and gas industry.

Shen says it is not easy to transplant US techniques to China as there are lots of geographic differences between the two nations. The depth of shale gas in the US is 500 meters to 2,600 meters while in China the reserves are usually found at a depth of more than 3,000 meters. Drilling costs increase considerably because of the increase in depth, he says.

Traditional fracking usually needs more than 10,000 cubic meters of water. Water may not be a big challenge in the US, but in China, a nation with nearly 1.4 billion people, the per capita water resources quota is just 2,100 cu m, or 28 percent of the global average. Using water to exploit shale gas seems like an extravagant way to tap the resources, Shen says.

Ye Dengsheng, general manager of a downhole service company at Chuanqing Drilling Engineering Co, an affiliate of China National Petroleum Corp, says that water will continue to be the main challenge for China's long-term shale gas goals.

He says that his Chengdu-based company has drilled as many as 18 shale gas wells in China. "For one well, we injected nearly 23,655 cu m of water, a record in China. We even made a huge man-made lake to store the water," he says.

In order to tackle these challenges, China needs to find its own way to exploit shale gas, which needs to be cheaper but also can save as much water as possible. Shen says that the answer lies in supercritical CO2.

Shen, who is a top-notch expert in water jet drilling, which uses high-speed and high-pressure water to drill, had not switched his research focus to supercritical CO2 until late 2003.

Leading a team looking into the worst blowout of natural gas and sulphurated hydrogen in Chongqing on Dec 23, 2003, Shen found that the special characteristics of CO2 and H2S might be the key reasons for the accident, which killed more than 200 people and sent another 2,000 to the hospital.

When CO2 reaches its critical point with a temperature of 31.1 C and a pressure of 7.38 MPa, it becomes supercritical CO2 fluid, which if inappropriately managed could cause catastrophes, but with proper use can be more powerful than water in terms of drilling.

He found that the earliest research on using supercritical CO2 in drilling was done in 1998 in the US. But the previous research was more about theories on paper. Previous research only indicated that supercritical CO2 could be used for drilling and was more efficient than water drilling.

Since then, Shen and his 30-member team have been working on the potentially promising technology at the China University of Petroleum.

Wang Haizhu, a postdoctoral student who has been working with Shen since the beginning of the research, says the biggest challenge was to prove the theory right in reality, which required a lot of research on paper and laboratory experiments.

"We have spent nearly 4 million yuan and several years on research and to build our own equipment for experiments to prove that supercritical CO2 has a desirable drilling performance," Wang says.

The test finally succeeded in April. "After hundreds of experiments, we can now safely say that supercritical CO2 can be used for drilling," Wang says.

The top priority for Shen's team is now to put the technology into mining operations. According to Wang, about 50 percent of the current drilling system has to be rebuilt to transport supercritical CO2 for underground operations.

He says that the feedback for the technology has been pretty good especially after China announced its shale gas goals earlier this year. "Since then, a lot of research institutes and oil companies have shown interest in our research," Wang says.

"I'm working on a detailed plan on how to put this technology into use. We have had only indoor experiments so far, but in another three to four years, we can put this technology into open air mining," he says.

Chen Mengfei contributed to this story.

mengjing@chinadaily.com.cn

(China Daily 08/03/2012 page5)

Today's Top News

Rescuers race against time for quake victims

Telecom workers restore links

Coal mine blast kills 18 in Jilin

Intl scholarship puts China on the map

More bird flu patients discharged

Gold loses sheen, but still a safe bet

US 'turns blind eye to human rights'

Telecom workers restore links

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|