A stitch in time

Updated: 2012-05-18 07:51

By Yao Jing (China Daily)

|

|||||||||||

|

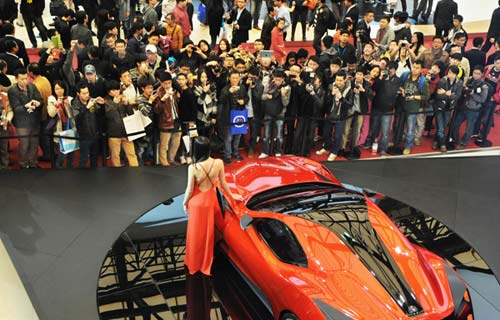

Yongzheng is known for its precision in delicate hand cutting and stitching of men's suits. provided to China Daily |

Quality edge helps iconic Chinese tailoring brand carve a niche in the West

For more than 200 years, Savile Row, in Mayfair, central London, has been held the world over as the mecca of men's bespoke tailoring.

But not too many people know that Yongzheng Tailor Shop, a famous Chinese brand, has been behind the success of several Savile Row brands. Established in the 1980s, Yongzheng Tailor Shop, has over the years not only become famous for its exquisitely hand-tailored suits, but is also a shining example of Chinese success in the international arena.

Known for its precision in delicate hand cutting and stitching of men's suits, Yongzheng has also emerged as a world leader in custom-made tailoring.

"More than 60 percent of all our orders come from the tailor shops in Europe and the United States. Customers in these regions choose the fabric and get themselves measured at the stores. These orders are then processed by our skilled craftsmen," says Wang Yongzheng, president and founder of the Tianjin-based Yongzheng Tailor Shop Group Co Ltd.

By no means are Yongzheng tailored suits cheap. The company charges from 3,000 yuan ($475, 369 euros) to more than 10,000 yuan for making a suit. The prices vary according to the difficulty of the techniques used.

Not surprisingly the company has built up an impressive list of high-profile clients over the years. Though Wang did not reveal any names, he indicates that several NBA stars were repeat customers.

"Due to the European economic crisis, many leading clothing establishments in Italy and France are tottering on the brink of bankruptcy. To avoid closure, many of the famous Western custom-made tailors are teaming up with Chinese tailoring establishments to stay afloat. Many of them have come to us as they are aware of our proven track record of more than 26 years."

Since 2008, Yongzheng's overseas orders have soared to nearly 30,000 compared with just 2,000 before. The company's revenue soared to more than 100 million yuan last year, with the bulk of it coming from men's suits, Wang says.

On average, the company now produces nearly 200 pieces of clothing every month. It took several days for a tailor to make just one suit when the company opened its doors.

Though most of the suits are still handmade, Wang says tailoring speeds have increased due to faster cloth preparation procedures. "Each garment goes through hundreds of procedures and is ironed elaborately with as many as 100 parts."

Despite the clarion calls from several Western companies for him to raise production, Wang has not done so as he considers exceptional quality the prime driver of success. "Some of my Western partners have urged me to hike output by 300 percent to 500 percent every year. But the maximum I can do is 10 percent to 20 percent," he says.

Justifying his point further, Wang says, haute couture depends largely on the handmade technique and the precision required at each step of the procedure. "We cannot sacrifice that for quantity. Quality is always the core competitive advantage for a tailor."

Though he enjoys considerable success abroad, Wang admits that it has been a tough call when it comes to connecting with high-end Chinese customers. "Most of them are obsessed with luxury brands like Prada, Louis Vuitton and Gucci. This has made our task more difficult," he says.

As far as the men's suit market is concerned, it is ultimately the customers who are the major drivers of change. "Right now it is the Western markets that are proving to be better hunting grounds."

With an eye on overseas opportunities, the company plans to open Yongzheng Tailor Shops in the US in the next five years, followed by similar outlets in Europe. Such a move will not only help brand-building among Western customers but also open the doors for more wealthy Chinese customers, he says.

Unlike several other companies that undertake OEM business for global brands, Yongzheng says his services are more sophisticated and are one-to-one services rather than volume manufacture.

Starting from a small shop in Tianjin's Tanggu district with an investment of 1,200 yuan in 1986, Yongzheng Tailor Shop is now an 80,000-square-meter garment production park in the city's Binhai New Area, an economic and technological development area.

Yongzheng has also invested a considerable amount of money to improve efficiency through better production techniques. At the same time, investments have also been made on new craftsmanship and pattern design, the two major factors behind its success.

The idea of developing the tailor-made business hit upon Wang in the 1990s, when more people started turning to tailors after being deterred by the high prices in shopping malls. Wang's tailor-made concept became an instant success and his clientele ranged from business tycoons to royalty and even included several key political personalities.

"Chinese customers lack knowledge on key aspects like image, identity, living habits and social occasions when it comes to choosing high-end clothing. Very often most of them do not know how to differentiate between a style and a pattern," Wang says.

Currently, Wang has nine shops and some 600 VIP customers in China. Most of the customers are wealthy Chinese with incomes in excess of $10 million.

Wang says that Yongzheng purchases nearly 1,000 kinds of dress material from several big global suppliers such as Scabal and Hield from Britain and Ermenegildo Zegna and Loroplana from Italy to make clothes for Chinese customers.

"The texture and availability can ensure the fundamental difference from garments that are industrially manufactured," Wang says.

In Yongzheng's Beijing shop, located on Wangfujing Street, the dark brown Italian-style wood furniture hardly gives an inkling of the rich array of garments made by the company.

The store manager, Wang Xiu, who has been working for the company for more than nine years, says Yongzheng has been through several tough challenges.

"Though the custom-made concept originated from the West, many customers did not trust and understand us in the beginning. Furthermore, the shop's initial understanding about the suit was just making some changes in collars, based on traditional collarless Chinese tunic suits."

All of that changed after the company started to attract more customers, she says. "It was then that we learnt the fine aspects, such as the essence of a suit. We know that a perfect suit has to match the soul of a person," Wang Xiu says.

The Beijing shop has more than 200 big-spending customers and netted a turnover of 15 million yuan last year.

Aside from keeping a sharp eye on new patterns and designs, Wang is also busy honing the foreign language skills of his tailors. "Although they (the tailors) possess the talent for the exquisite craft, they very often do not know how to speak English," Wang says.

This, he explains, is an important part of the company's overseas plans.

yaojing@chinadaily.com.cn

(China Daily 05/18/2012 page17)

Today's Top News

Rescuers race against time for quake victims

Telecom workers restore links

Coal mine blast kills 18 in Jilin

Intl scholarship puts China on the map

More bird flu patients discharged

Gold loses sheen, but still a safe bet

US 'turns blind eye to human rights'

Telecom workers restore links

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|