3D printing reshapes manufacturing

Updated: 2013-02-18 10:48

By Wang Ying in Shanghai (China Daily)

|

|||||||||||

Modern manufacturing features mass production and standardization but it has faced an increasing challenge to satisfy more individual requirements from clients since the start of the 21st century. Therefore, demand for tailor-made products makes 3D printing possible, said Lu.

"Three years ago, we spent about 1 million yuan ($160,000) in developing two models to make the outer shell of a car within three months. Similar development using traditional methods requires more than one year and will cost tens of millions of yuan from making the initial model to manufacturing in bulk," said Lu.

However, Lu also noted such production cannot completely replace traditional manufacturing, especially for products that need to be made in large amounts and feature a high degree of similarity.

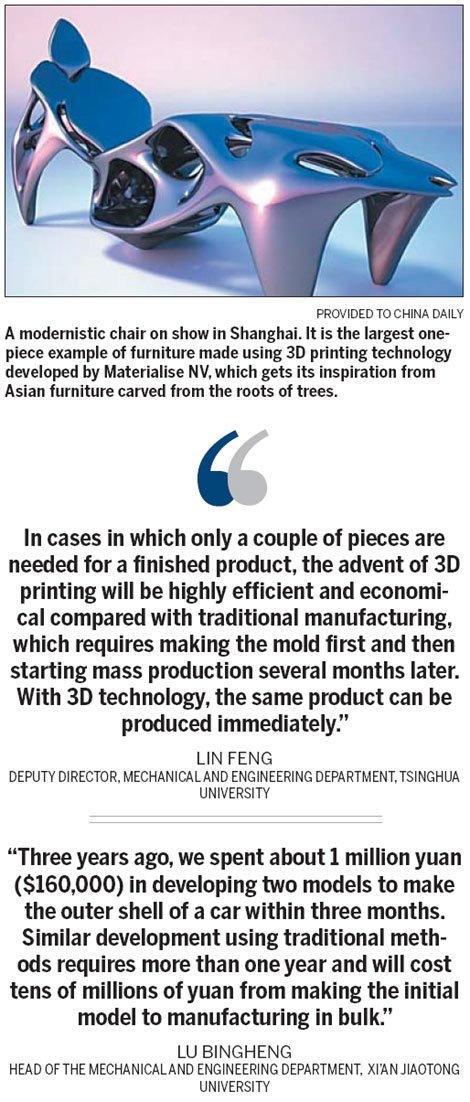

In the eyes of Wim Michiels, executive vice-president at Materialise NV, 3D printing is better for the environment in that there is no need to set up a full production line, which can involve a lengthy amount of time, high costs and the possible failure of the first sample due to imperfect accuracy.

"3D printing is faster and you can bring your products to the market ahead of your rivals. In addition, you have no limitations in design with this technology," Michiels said.

Although theoretically 3D printing technology can print anything from a house to a car, it needs time to test the products before they can become practical in daily life, said Lin of Tsinghua University.

"After more than a decade's research into 3D printing, people are gradually beginning to accept this new manufacturing concept. Of the two main opposing opinions, one has doubts about the production technology while the other has excessively high expectations," said Lu of Xi'an Jiaotong University.

He added that both opinions are biased. "3D printing technology is consistently improving. It just needs more research and development to make it possible to print objects using various materials. It is also worth noting there is no technology that can do absolutely anything," Lu said.

Many Chinese enterprises are keeping a close eye on the market potential for 3D printing and have started to develop their own printers. Beijing Tiertime Technology Co is one such example. The company has so far sold several thousand sets to the United States, but only several hundreds in the Chinese market.

Related Stories

Lucasfilm pushes pause on 3-D 'Star Wars' prequels 2013-01-29 10:11

'2012 3D' set to blow audiences' minds 2012-11-12 17:07

Dragons in 3-D 2012-08-04 07:46

Ang Lee's 3D 'Life of Pi' opens NY film festival 2012-10-01 14:54

'Frankenweenie 3D' premieres in London 2012-10-12 09:01

3-D 'Titanic' past $2 billion mark 2012-04-16 15:50

Today's Top News

Police continue manhunt for 2nd bombing suspect

H7N9 flu transmission studied

8% growth predicted for Q2

Nuke reactor gets foreign contract

First couple on Time's list of most influential

'Green' awareness levels drop in Beijing

Palace Museum spruces up

Trading channels 'need to broaden'

Hot Topics

Lunar probe , China growth forecasts, Emission rules get tougher, China seen through 'colored lens', International board,

Editor's Picks

|

|

|

|

|

|