Raising dragons from the water

Updated: 2011-06-03 07:46

By Li Wenfang (China Daily)

|

|||||||||||

GUANGZHOU - With the Dragon Boat Festival just around the corner, Shangjiao village is a scene of hustle and bustle.

|

|

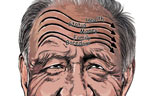

Dragon boat maker Deng Jiyong, 40, is busy processing orders at a boat building yard in Shangjiao village in Guangzhou, Guangdong's biggest dragon boat manufacturing base, on May 30. Zou Zhongpin / China Daily |

Home to eight dragon boat building yards producing more than 80 percent of Guangdong province's dragon boats, the village is filled with the noise of drilling and nailing. In the air wafts the smell of fresh paint.

Deng Jiyong, 40, along with a few colleagues, is racing to process orders in the Chen-Hanhui Dragon Boat Yard, the biggest of its kind in the village. Several electric fans fixed onto the roof add noisy whirrs.

A few ready-made dragon heads and tails wait quietly outside the workshop to be attached to the boats before the coming weekend. In the waterways around the workshop a few other nearly finished boats float.

"These are the busiest days for us. We have to work overtime to meet the deadline," said Deng, who earns 110 yuan ($17) a day for more than 10 hours in the building yard.

A native of the village, in Panyu district of Guangzhou city, Deng said he grew up watching the building of dragon boats.

With sawdust covering his body, even his eyelashes, Deng works through all the steps in making a boat, including the most demanding part - cutting the wood to be connected into the keel and the sides of a boat. The cutting should be so precise and smooth that even a thread of hair cannot get into the joint, Deng said.

Cutting only one side of the 20-cm joint takes a skilled worker about two hours, and a long dragon boat needs 14 such cuts.

"It requires good vision, and only a master can do it," Deng said.

With more than 14 years in the trade, Deng said he is still far from being one of the masters who oversee the building of a boat that requires different lumber for its various parts, usually Pontianak wood from Southeast Asia, fir wood or the most expensive teak wood.

A dragon boat 40 meters long requires six square meters of lumber and takes four people working overtime about 16 days to finish.

If it is made of Pontianak wood, it sells for more than 100,000 yuan.

Deng and his colleagues started to process their 10-boat order for this year soon after the Spring Festival.

By next Monday, Deng said he will be finished making dragon boats for the year, and can return to construction work or growing flowers like most of his fellow villagers.

People in Guangdong have a long tradition of hosting dragon boat races between townships and villages each year around the Dragon Boat Festival, which has sustained the village's traditional dragon boat building for more than 300 years.

In fact, local people have such a strong attachment to dragon boats that building one is like building a mini temple, Deng said.

A dragon boat usually also carries a shrine in the middle for racers to offer incense or sacrifices before or after a race.

Dragon boats made in Deng's village have long been regarded as the standard for others to follow.

In its peak in the 1980s, the village had more than 30 dragon boat building yards, processing hundreds of orders a year from home and abroad.

However, the demand for traditional dragon boats decreased in the 1990s partly because of mass-produced dragon boats made of rubber or plastic, which cost less.

In its slowest year, the building yard Deng works for received orders for only three boats.

However, over the past few years, with a revival in traditional culture, the inclusion of dragon boat racing in the Asian Games and a rapid increase in family incomes, there has been a rebound of demand for traditional dragon boats.

"Dragon boats made of wood perform the best in races," Deng said. "That's because wood has a flexibility in the water incomparable with other materials."

However, Deng admitted that traditional dragon boat building is "hard and doesn't make much money".

Apart from being seasonal, the job is tiring and dirty, Deng said.

Most of his colleagues were born in the 1970s and Deng considers them the last generation in this business.

"I didn't have much education and boat making, construction and flower growing were the main business in our village," he said.

With a son and daughter in high school, Deng hopes they can land a better profession.

He does, however, feel a sense of accomplishment when a boat is finished and praised by the client, and at the dragon boat races he compares the boats made by his yard with those from other yards.

"It makes me very happy and excited," the boat maker said.